Introduction of Impressed Current Cathodic Protection

HOME > Introduction to Cathodic protection > Introduction of Impressed Current Cathodic Protection

Types of cathodic protection methods

| Element | Secrificial anode system | Impressed current system |

|---|---|---|

| types of cathodic protection methods | Mg Anode, Al Anode, Zn Anode | H.S.C.I Anode, M.M.O Anode |

| construction method | - | Deep Well Bed, Shallow Bed |

| pros |

|

|

| cons |

|

|

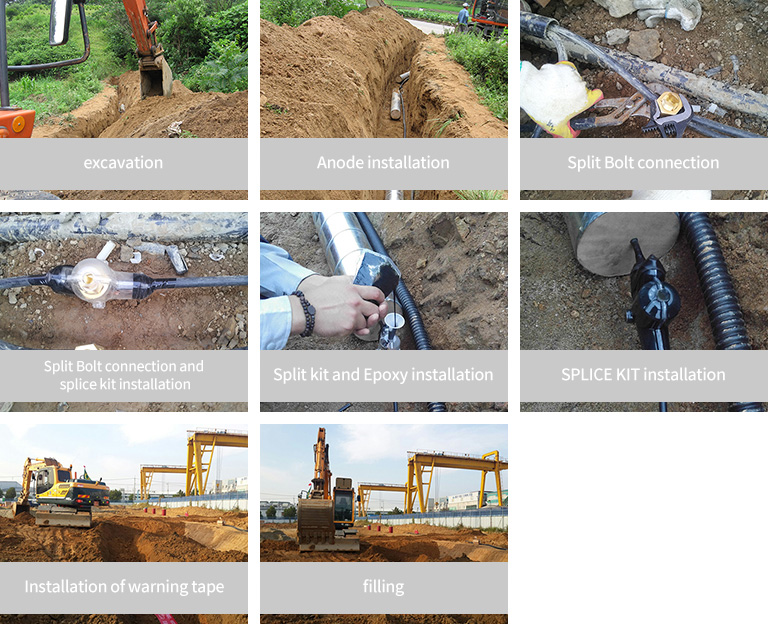

Deep Well Bed

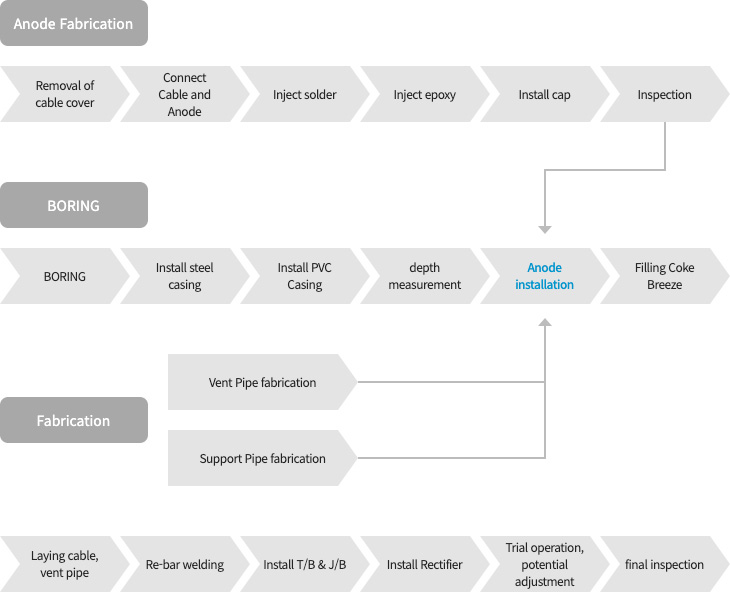

WORK PROCESS

-

Anode Fabrication

Removal of

cable coverConnect

Cable and AnodeInject solder

Inject epoxy

Install cap

Inspection

-

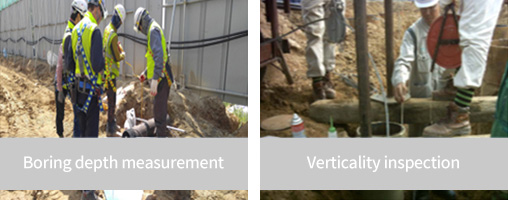

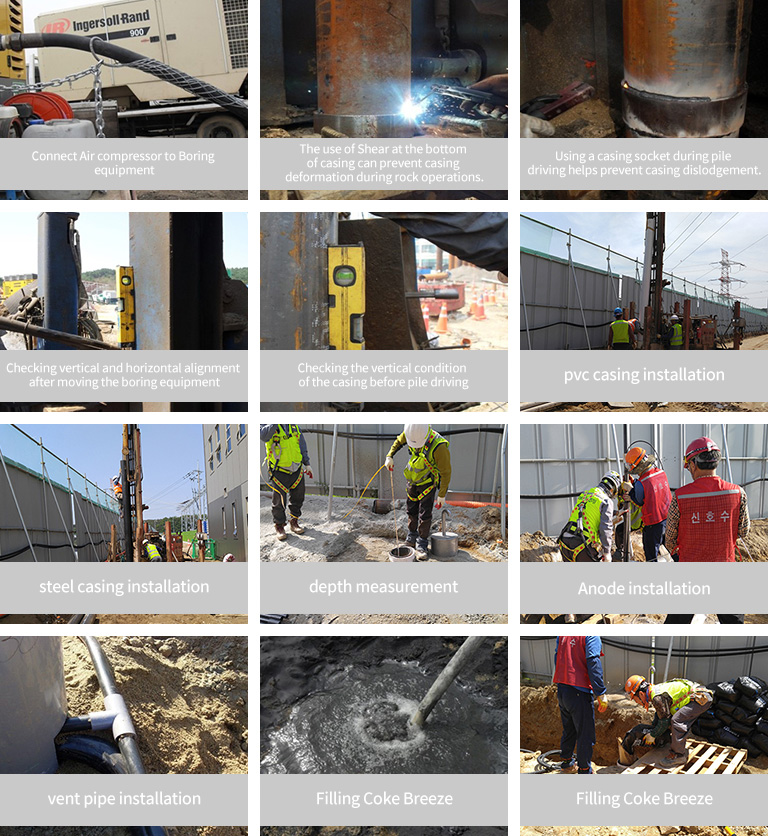

BORING

BORING

Install steel casing

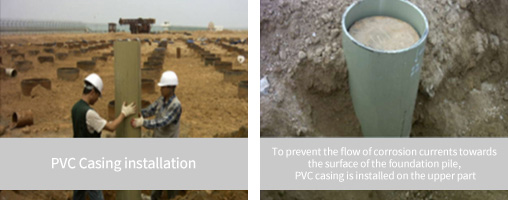

Install PVC Casing

depth measurement

Anode installation

Filling Coke Breeze

-

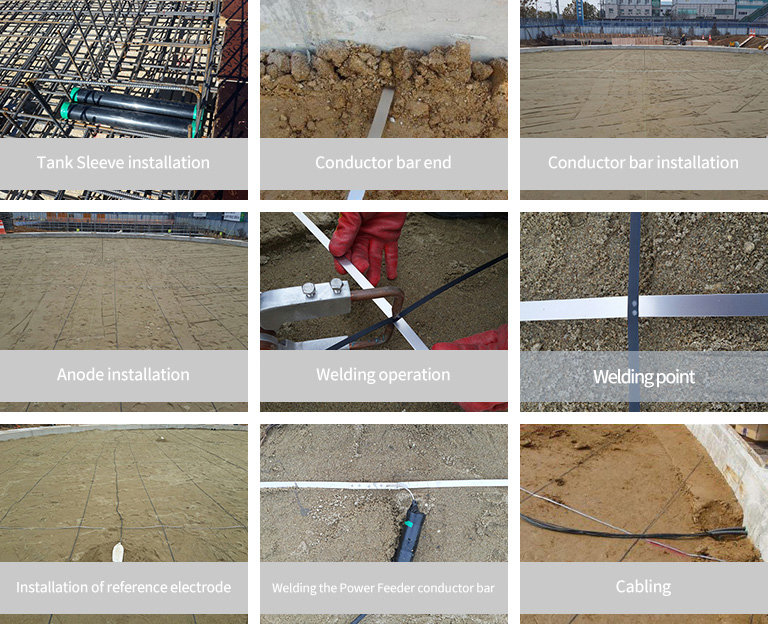

Fabrication

Vent Pipe fabrication

Support Pipe fabrication

Laying cable, vent pipe

Re-bar welding

Install T/B & J/B

Install Rectifier

Trial operation, potential adjustment

final inspection

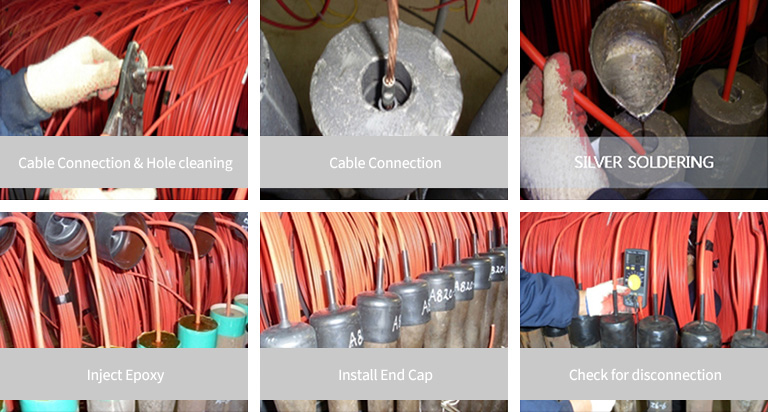

Anode Fabrication

BORING

After Boring, Insulation of Steel Pipes

Boring Hole inspection

Anode installation

Vent Pipe fabrication

Filling Coke Breeze

Negative Cable connection

Installation T/B & J/B & Rectifier

SHALLOW

Tank bottom

deep well

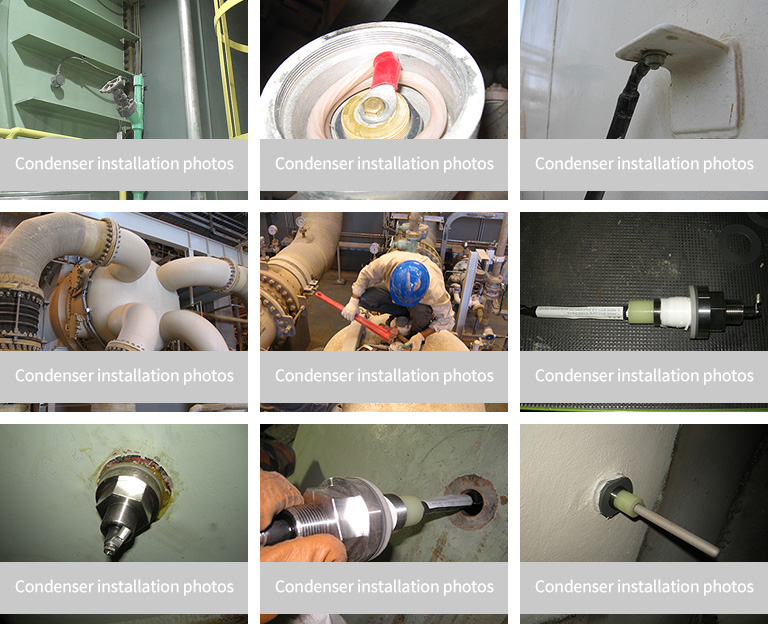

Condenser

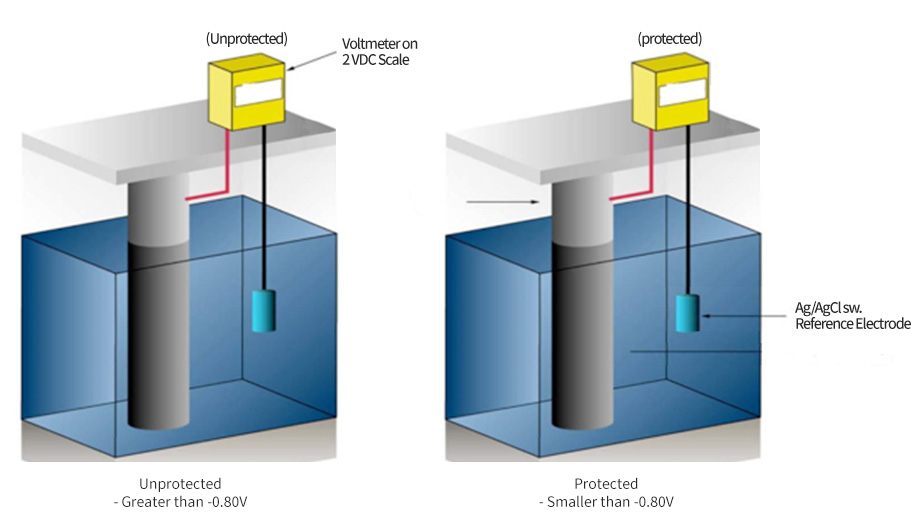

Potential Measurement Method

- Natural Potential Measurement: Measure in a state without applied impressed current.

- Protective Potential Measurement: Measure after applying impressed current using a rectifier.

Potential measurement procedure :

Rectifier off

Measure natural potential

Rectifier on

Measure Protective potential